Optimizing Performance: Picking the Right Aftermarket Construction Parts for Your Fleet

Optimizing Performance: Picking the Right Aftermarket Construction Parts for Your Fleet

Blog Article

Increase Efficiency With Aftermarket Components: an Overview for Heavy Machinery Owners

Benefits of Aftermarket Parts

Proprietors of hefty machinery can delight in various benefits by deciding for aftermarket components over initial tools maker (OEM) parts. Aftermarket parts are typically more affordable than OEM parts, allowing equipment owners to reduce upkeep and repair service expenses without compromising on quality.

Considering that aftermarket manufacturers specialize in creating details components, equipment owners have accessibility to a broader variety of alternatives to suit their requirements. Aftermarket components are known for their high quality and integrity, with many meeting or going beyond OEM standards.

Finally, picking aftermarket components can additionally result in faster repair services and lowered downtime. With easier accessibility and fast delivery options, equipment proprietors can get their devices up and running once again promptly, minimizing disruptions to their operations.

Choosing the Right Aftermarket Parts

When taking into consideration aftermarket components for heavy machinery, it is vital to focus on compatibility and top quality to make certain optimal performance and longevity of the devices. Choosing the ideal aftermarket components can be an essential choice for hefty equipment proprietors as it straight affects the performance and integrity of their tools.

Secondly, top quality must never ever be compromised when choosing aftermarket components (aftermarket construction parts). Opting for top quality components guarantees toughness, integrity, and general performance of the machinery. It is advisable to resource aftermarket parts from reputable producers or vendors recognized for their top quality criteria

Furthermore, thinking about elements such as warranties, consumer testimonials, and compatibility with existing systems can additionally help in making the right selection. By focusing on compatibility and high quality when selecting aftermarket parts, heavy equipment proprietors can enhance the performance and long life of their devices.

Installation and Upkeep Tips

For efficient procedure and durability of hefty machinery, correct installation and normal upkeep are vital. When installing aftermarket components, ensure that you very carefully follow the maker's instructions to ensure ideal efficiency. It is necessary to Homepage make use of here are the findings the appropriate devices and techniques to stop any kind of damage during the installation process. Regular upkeep is vital to maintain your machinery running smoothly. Create a maintenance routine that consists of jobs such as checking fluid degrees, inspecting for deterioration, and cleansing elements (aftermarket construction parts). Without delay deal with any type of concerns that arise to stop more damages and expensive fixings. Additionally, consider purchasing training for your maintenance personnel to guarantee they have the essential abilities to identify and deal with prospective issues. By focusing on installment and upkeep treatments, you can optimize the performance and life expectancy of your hefty equipment, inevitably conserving money and time in the lengthy run.

Cost-Effectiveness of Aftermarket Components

Appropriate setup and normal upkeep are fundamental facets for hefty equipment proprietors intending to analyze the cost-effectiveness of aftermarket components for their equipment. While original equipment producer (OEM) parts are understood for their high quality, aftermarket parts provide a more affordable solution without jeopardizing performance. By thoroughly assessing the high quality and compatibility of aftermarket parts with their machinery, owners can strike a balance in between cost-effectiveness and efficiency, eventually optimizing the performance and durability of their heavy devices.

Taking Full Advantage Of Efficiency With Aftermarket Upgrades

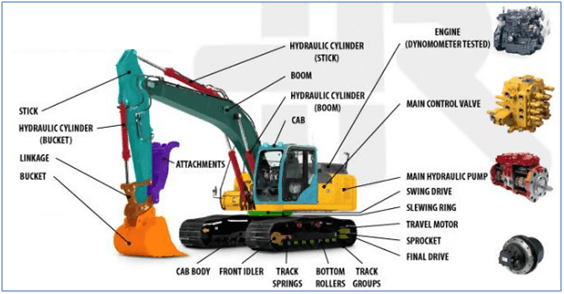

To enhance functional efficiency and efficiency, heavy equipment proprietors can successfully make best use of performance with tactical usage of aftermarket upgrades. Aftermarket upgrades offer the possibility to tailor heavy equipment to particular operational demands, leading to enhanced functionality and result. Upgrading components such as engines, transmissions, hydraulic systems, and tracks can substantially boost the total effectiveness of the machinery.

Regularly examining the efficiency of heavy equipment and recognizing areas where aftermarket upgrades can be helpful is important for making best use of efficiency. By buying high quality aftermarket components and upgrades, machinery owners can accomplish greater degrees of efficiency, eventually causing set you back savings and boosted operational results.

Final Thought

Finally, aftermarket parts provide many advantages for hefty equipment owners, including cost-effectiveness, boosted performance, and customization options. By choosing the best aftermarket parts, complying with appropriate installment and maintenance procedures, and making best use of upgrades, hefty equipment proprietors can enhance their equipment's efficiency and long life. Purchasing aftermarket components can eventually cause enhanced efficiency and minimized downtime, making it a beneficial factor about his to consider for owners wanting to enhance their machinery operations.

Proprietors of hefty machinery can take pleasure in various benefits by opting for aftermarket parts over original tools supplier (OEM) components. Aftermarket parts are generally much more cost effective than OEM components, enabling machinery proprietors to minimize upkeep and repair work costs without jeopardizing on high quality. By thoroughly evaluating the top quality and compatibility of aftermarket components with their machinery, owners can strike a balance between cost-effectiveness and performance, ultimately maximizing the efficiency and long life of their heavy equipment.

In verdict, aftermarket parts supply numerous benefits for heavy machinery proprietors, consisting of cost-effectiveness, boosted efficiency, and customization alternatives. By selecting the right aftermarket components, complying with appropriate installment and maintenance treatments, and maximizing upgrades, hefty machinery proprietors can boost their devices's performance and longevity.

Report this page